Finding the Best Work Boots for Men: A Guide to Custom-Fit Craftsmanship

Finding the right pair of work boots is about more than just picking a size. It’s an investment in a critical tool for your trade, one that promises uncompromising safety, lasting durability, and a perfect, personalized fit. Think of it as commissioning a piece of equipment designed to support you through the toughest days on the job, blending traditional craftsmanship with modern innovation.

Your Foundation for Choosing the Right Work Boots

Selecting the right work boots comes down to matching the footwear to what your job throws at you every day. A carpenter wouldn't use a sledgehammer for a finishing nail, and in the same way, a lineman needs entirely different protection than a warehouse manager. This is where an educational approach to footwear truly matters.

This guide is here to bridge the gap between old-world craftsmanship and modern safety technology. We'll show you how our direct-to-consumer model, built on partnerships with global artisans, makes custom-fit, handcrafted boots accessible. Our goal is to empower you to design a boot that works as hard as you do, without the traditional retail markup.

What Really Matters in a Work Boot

When you cut through the marketing noise, a few core elements define a truly exceptional work boot. By focusing on these essentials, you'll create a pair that delivers performance, style, and value for years to come.

- Durable Materials: The foundation of any long-lasting boot is the quality of its components, from full-grain leather uppers sourced for their character to tough, reliable outsoles.

- Critical Safety Features: Toe protection, slip resistance, and electrical hazard ratings are non-negotiable in many professions, and integrating them shouldn't mean sacrificing comfort.

- A Perfect, Personalized Fit: A boot that doesn’t fit correctly can lead to fatigue and long-term foot problems. Personalization and a custom fit are key for anyone who needs all-day comfort and support.

The growing emphasis on workplace safety has had a huge impact on the footwear industry. In fact, in 2024, the global work boots market hit about $13.57 billion. That number is driven by strict safety regulations across hazardous industries, highlighting the critical role your footwear plays in today's workplaces.

A well-chosen work boot is more than just protection; it's a piece of performance equipment. By investing in quality craftsmanship and a personalized fit, you're not just buying boots—you're commissioning a tool for your own daily comfort and safety.

Proper maintenance is also a huge part of making your investment last. Once you’ve found that perfect pair, taking care of it is essential. For expert tips on preserving the leather and ensuring longevity, explore our guide on how to clean leather boots.

To simplify your search, we've put together a quick-reference guide. This table matches common professions with the boot features that matter most, helping you focus on what you truly need.

Work Boot Feature Checklist by Profession

| Profession | Essential Safety Feature | Recommended Material | Key Comfort Factor |

|---|---|---|---|

| Construction Worker | Steel or Composite Toe, Puncture-Resistant Sole | Full-Grain Leather | Shock-Absorbing Midsole, Good Ankle Support |

| Electrician | Electrical Hazard (EH) Rated | Leather or Non-Conductive Synthetics | Lightweight Design, Cushioned Insole |

| Warehouse Staff | Slip-Resistant Outsole, Composite Toe | Leather/Mesh Combo for Breathability | Flexible Sole, Arch Support |

| Welder | Metatarsal Guard, Heat-Resistant Sole | Flame-Resistant Treated Leather | Snug Fit to Prevent Debris Entry |

| Plumber | Waterproof Membrane, Slip-Resistant Outsole | Waterproof Leather, Rubber | Moisture-Wicking Lining |

Using this checklist is a great starting point. It helps ensure you're not just buying a good boot, but the right boot for your specific daily grind.

Decoding Boot Materials and Craftsmanship

The soul of a great work boot lies in two things: the materials it’s made from and the artistry of its construction. When you’re seeking the best work boots for men, you're really judging this combination of premium materials and proven technique. It's what separates a boot that lasts a single season from one that becomes a trusted partner for years.

It all begins with the leather. While many boots look similar on the shelf, the type and grade of leather used create a massive difference in performance and longevity. Understanding these distinctions is the first step toward a more informed choice.

Leather Quality and Character

Not all leather is created equal. The types you'll most often encounter each have unique characteristics suited for different jobs and environments.

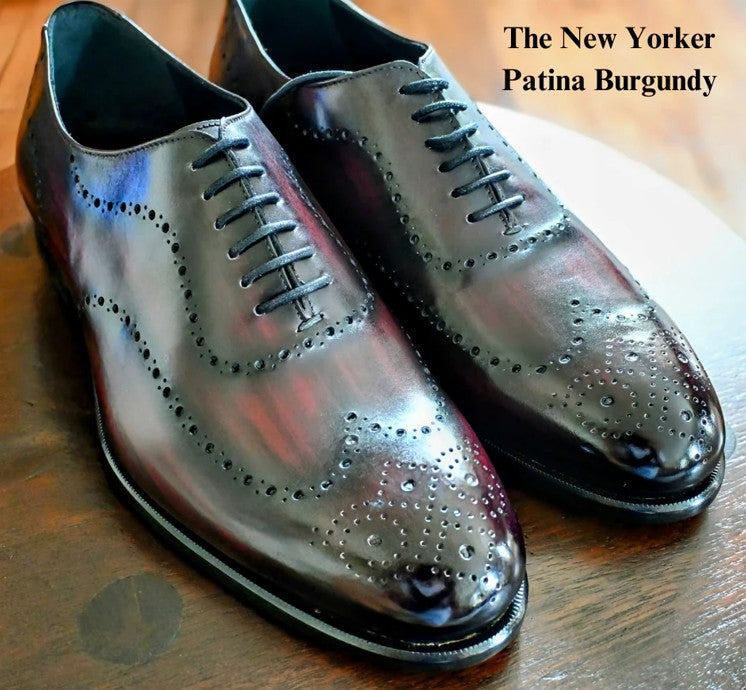

- Full-Grain Leather: This is the pinnacle of quality. As the outermost layer of the hide, it retains all the natural grain and character. It’s incredibly tough, breathable, and develops a rich, beautiful patina over time.

- Top-Grain Leather: A close second, this leather is sanded to remove imperfections. This process makes it slightly more flexible than full-grain, but it won't have the same iron-clad durability in the long run.

- Nubuck and Suede: These leathers are buffed to create a signature soft, velvety feel. While exceptionally comfortable, they are less resistant to water and abrasion, making them better suited for lighter-duty work or office-to-site transitions.

A welder, for example, needs a thick, full-grain leather boot that can shrug off heat and sparks. A project manager who splits time between the office and the job site might prefer the more refined look and immediate comfort of nubuck, which delivers on style without needing to be built like a tank.

The Hallmark of Quality Construction

Beyond the leather itself, the construction method is what truly separates a disposable boot from a long-term investment. How the upper is attached to the sole determines its durability, water resistance, and—critically—whether it can be repaired.

The gold standard in bootmaking is, without a doubt, the Goodyear welt. This time-honored process involves stitching a tough strip of leather (the "welt") to both the upper and the insole. The outsole is then stitched directly to that welt, creating an incredibly durable, water-resistant boot that can be resoled again and again.

This technique is a hallmark of true craftsmanship, blending traditional skill with modern needs. It is more labor-intensive, but it means your favorite boots can be given a new lease on life with a fresh sole, extending their usefulness for years. In contrast, cemented construction, where the sole is simply glued on, is faster and cheaper but lacks longevity. Once that sole wears out, the boot is typically finished. If you want to dive deeper into why this traditional method remains superior, explore our ultimate guide to Goodyear welt construction.

Ultimately, selecting the right boot is about understanding this blend of quality materials and skilled handiwork. It's a chance to customize your gear, ensuring the boots on your feet are perfectly matched to your daily demands.

Getting Serious About Modern Safety Features

When you’re trying to find the best work boots for men, safety features are absolute dealbreakers. They're what stand between you and a trip to the emergency room. It's easy to get lost in technical specs, but understanding the essentials allows you to select a boot that's perfectly matched to the hazards you face daily. The good news? Modern boot technology means you no longer have to sacrifice comfort for top-tier protection.

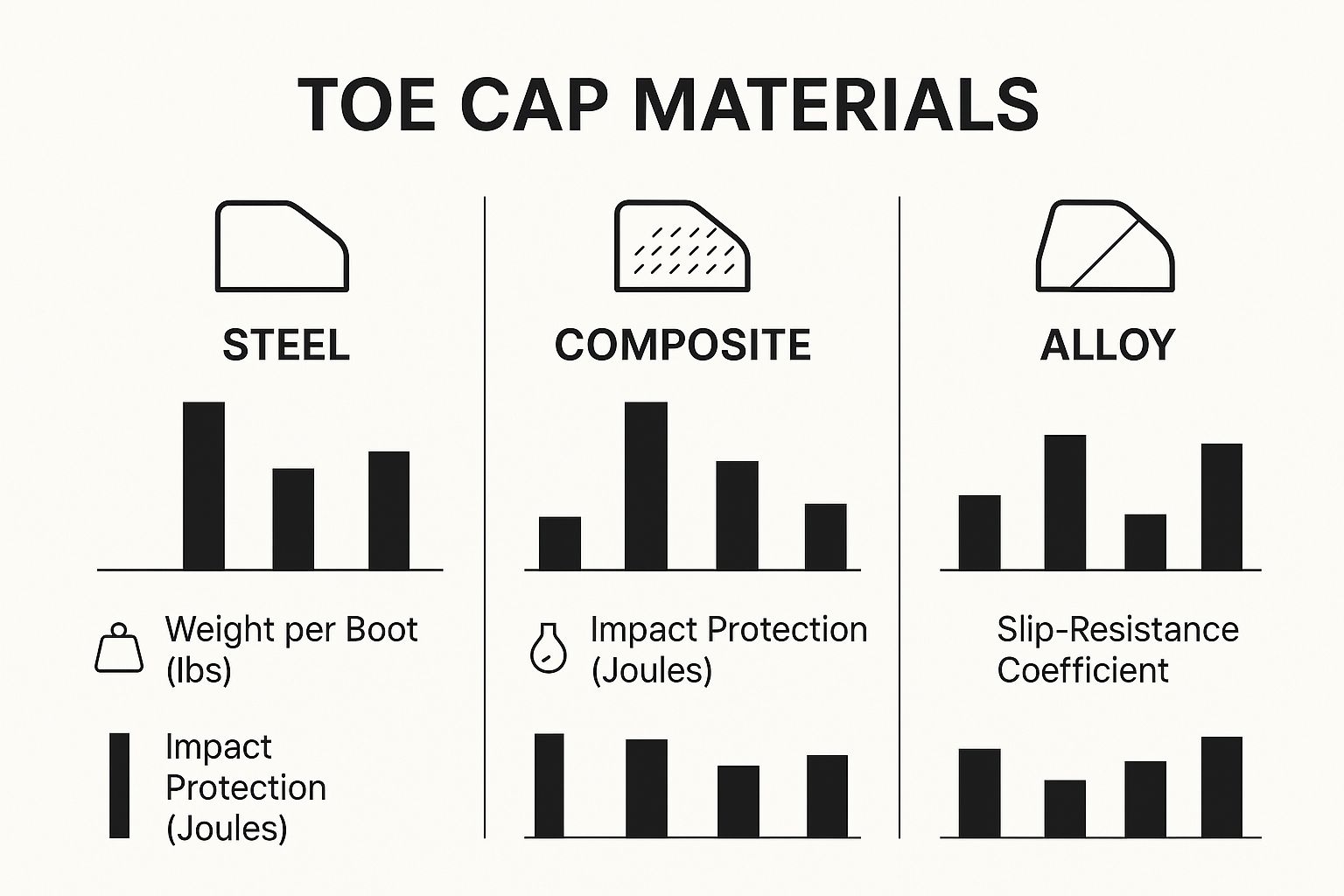

At the heart of every true work boot is its protective toe—your primary defense against falling equipment or compression. The material inside that toe cap makes a huge difference in how your feet feel at the end of the day. Old-school steel toes are famous for their brute strength, but they're heavy. Lighter options like composite and alloy toes now offer incredible protection without the extra weight, which significantly cuts down on fatigue over a long shift.

More Than Just a Steel Toe

Real-world safety goes far beyond the toe cap. Different job sites present unique risks, and the best boots are built with specialized technology to handle them. The outsole, for example, is engineered for very specific conditions.

Picture an auto mechanic walking across a greasy shop floor versus a roofer working on a steep pitch. The mechanic absolutely needs a boot with an oil- and slip-resistant sole, typically made from a rubber compound with treads designed to channel liquids away. The roofer, on the other hand, needs a sole that provides an almost sticky grip on dry, angled surfaces. It's all about matching the technology to the task.

To help you decide what's right for you, let's break down the three main types of safety toes. Each has its own set of pros and cons depending on your job's demands.

Protective Toe Caps: A Head-to-Head Comparison

| Toe Type | Weight | Protection Level | Best For |

|---|---|---|---|

| Steel | Heaviest | Maximum impact & compression | Construction, heavy manufacturing, and environments with extreme hazards. |

| Alloy | Lighter than steel, heavier than comp | High, similar to steel | Those needing steel-like protection with less weight and a roomier toe box. |

| Composite | Lightest | Good, but can crack under extreme impact | Electricians (non-conductive), airport workers, and jobs requiring metal-free footwear. |

While steel still reigns supreme for sheer toughness, you can see that composite and alloy options deliver serious protection without weighing you down.

Specialized Protection for High-Risk Jobs

For those in trades with very specific dangers, you need to look for additional, specialized features. If you're an electrician, a boot with an Electrical Hazard (EH) rating isn't a nice-to-have; it's a must. These boots are constructed with non-conductive materials to insulate you from the ground, providing a secondary source of protection against live circuits.

For anyone walking across a construction site littered with nails and other sharp debris, a puncture-resistant plate is non-negotiable. This plate, made from either steel or a more flexible composite material, is built into the midsole to stop sharp objects from punching through the sole. This is the kind of detail that separates a good boot from a great one.

Picking the right safety features isn't just about checking off boxes. It’s about conducting a quick risk assessment of your own job. When you match the boot’s technology to your actual daily tasks, you’re creating a personalized shield that works just as hard as you do.

The growing demand for this level of protection is a clear sign of a bigger industry trend. The global work boots market is expected to hit about $17.7 billion by 2025 and swell to $23.14 billion by 2032. This boom is driven by tougher safety regulations and a greater awareness of occupational hazards. Of course, your boots are just one part of a comprehensive safety plan, which includes a full range of essential safety supplies for any work site.

Achieving All-Day Comfort and a Perfect Fit

A work boot that doesn’t fit right is more than just an annoyance—it's a productivity killer that can lead to blisters, fatigue, and even chronic pain. When you're searching for the best work boots for men, achieving a perfect, personalized fit isn't a luxury; it's an absolute necessity. The secret is to look beyond standard sizing.

A common mistake is forgetting that feet change during the day. After hours of standing and walking, your feet naturally swell. Because of this, you should always try on new boots at the end of your workday. This ensures the most accurate measurement and helps you avoid buying a pair that feels great in the morning but painfully tight by quitting time.

Beyond Standard Sizing

A true fit is about more than just length. You must consider the entire volume of your foot—width, instep height, and arch shape are all critical pieces of the puzzle. This is where mass-produced boots can fall short and a personalized, custom approach makes all the difference.

To achieve that flawless fit, focus on these areas:

- Foot Volume and Width: If a boot feels tight across the top or sides, you likely need a wider size or a boot built on a different last (the mold a boot is shaped around). A good fit allows your toes to splay naturally, not feel cramped.

- Arch Support: The right arch support is a game-changer. It aligns your foot correctly, taking significant strain off your knees, hips, and back. Look for boots with robust built-in insoles or enough room to add your own orthotics.

- Heel Lock: Your heel should feel snug and secure, with minimal movement. A little slip is normal during the break-in period, but excessive rubbing is a recipe for blisters.

A boot built for your unique foot shape is not just gear; it's a personalized tool that prevents common problems before they start, completely transforming your day-to-day performance on the job.

Modern Comfort Technologies Explained

Footwear technology has come a long way, bringing incredible advancements in comfort. Today’s best work boots often feature designs specifically to fight the fatigue that comes from a 10-hour shift on hard concrete. Take anti-fatigue midsoles, for instance. Typically made from materials like EVA foam, they act like shock absorbers, dispersing the impact of every step.

Memory foam insoles are another huge win for comfort. They mold to the unique contours of your foot, providing customized cushioning right where you need it most. This level of personalization makes a massive difference in reducing pressure points and keeping you comfortable all day long. This industry focus on blending tough function with smart ergonomics is driving serious growth. The global work boot market is projected to hit an estimated $26.3 billion by 2032, pushed forward by innovations like lighter composite safety toes and advanced moisture-wicking linings. You can learn more about these work boot trends dominating 2025 on CebuWorkBoots.com.

Even the most perfectly sized boots need a break-in period to truly feel like your own. High-quality leather, in particular, needs time to soften and conform to your foot. To make this process go smoothly, it helps to know the right way to do it. For expert advice, check out our guide on how to break in new shoes and get off to a more comfortable start.

How to Design Your Own Custom Work Boots

This is where your knowledge of materials, fit, and safety features culminates. When you design your own work boots, you're not just making a purchase you're creating a personalized tool built specifically for you and your trade. Our Design Lab brings old-world craftsmanship and modern design right to your fingertips, making artisan quality truly accessible.

The process begins with the last. Think of the last as the three-dimensional mold that gives the boot its core shape and fit. Choosing the right last is the most critical part of the design, as it dictates the boot's volume, arch support, and overall feel. A well-chosen last ensures your boot feels like an extension of your foot from the very first wear.

Building Your Boot from the Ground Up

With your foundational fit locked in, it’s time to select your materials. This is your chance to match the leather to your job site. A welder might opt for a thick, oil-tanned leather for its fantastic heat resistance. A project manager, on the other hand, could choose a polished full-grain leather for a cleaner look that still holds up to wear and tear.

Next is the outsole—the point of contact with the ground. This decision is all about function. An ironworker climbing beams needs a boot with an aggressive, high-traction Vibram sole for a solid grip. In contrast, a mechanic on a slick concrete floor will want an oil- and slip-resistant rubber compound to stay safe.

Customization is about creating a boot without compromises. It's the fusion of your personal style with the practical demands of your job, resulting in footwear that is perfectly tailored to how you work and live.

Adding the Finishing Touches

Once the main components are chosen, you can dive into the details that make the boot uniquely yours. This includes everything from the color of the stitching and the style of the eyelets to adding a custom monogram. These small touches transform your work gear into a statement of personal style and craftsmanship.

This level of control isn't just for boots. The same principles of customization apply across all types of footwear, allowing you to dial in both aesthetics and function. For inspiration on how this works with more casual styles, check out our guide on how to design your own sneakers.

Ultimately, you end up with a pair of the best work boots for men for one simple reason: they were designed by you, for you. Every element, from the last to the laces, was chosen for a purpose. Our direct-to-consumer model connects you with skilled global artisans, guaranteeing a high-quality, handcrafted boot that performs exactly as you need it to, day after day.

A Few Final Questions on Finding the Right Work Boots

Picking the right work boot is a big decision, and it's normal to have questions before you commit. We've gathered some of the most common inquiries to help you feel confident that you're getting the best pair for your needs.

One of the biggest questions is about the break-in period. A quality pair of full-grain leather boots needs time to get acquainted with your feet. Think of it as a gradual process, usually taking about one to two weeks, where the initially stiff leather softens and molds perfectly to your foot's unique shape. The end result is a fit that feels truly custom-made.

How Long Should a Good Pair of Work Boots Last?

This is the million-dollar question, and the answer depends on the boot's construction, materials, and daily wear. A boot made with Goodyear welt construction is built for the long haul because the sole can be completely replaced, extending its life far beyond boots with glued-on soles.

If you’re in a demanding field like construction or welding, you can expect a premium pair to last one to two years before needing a resole. For those in less intense jobs, they can last much longer. The key, of course, is proper care—regular cleaning and conditioning make all the difference.

Getting the Sizing and Fit Just Right

Nailing the right size, especially when ordering custom boots online, can feel tricky. The most important thing to remember is that your boot size is likely not the same as your sneaker size.

A perfect fit boils down to these three things:

- A Snug Heel: Your heel should feel locked in. A tiny bit of lift when you walk is okay, but it shouldn't be slipping all over the place.

- Toe Wiggle Room: You need enough space to move your toes freely. They should never be crammed against the end of the boot.

- The Right Width: Your foot shouldn't feel squeezed. It should be comfortable and supported from side to side.

A proper fit is the absolute foundation of all-day comfort and safety. Taking a few extra minutes to measure your feet and understand these details ensures you get a boot that works with you, not against you.

Finally, we often get asked: "Do I really need a safety toe?" The answer is simple. If there's any risk of falling objects or compression on your job site, then yes, a safety toe is non-negotiable. The good news is that modern composite and alloy toes offer incredible protection without the weight of traditional steel, making them a fantastic choice for many professionals.

Ready to build a boot that’s made exclusively for you? At Alexander Noel, our Design Lab lets you combine true artisan craftsmanship with your exact specifications. Start designing your perfect pair of custom work boots today!

![Men's Shoe Trends 2026: 7 Game-Changing Styles [Alexander Noel Guide]](http://www.shopalexandernoel.com/cdn/shop/articles/hero_alexander_noel_final_1024x1024.png?v=1767751739)