The Enduring Value of Goodyear Welt Construction

A Goodyear welt isn't just a component in a shoe; it's the architectural foundation that defines truly exceptional footwear. Think of it as the secret handshake of quality craftsmanship—a time-honored technique that creates shoes built for durability, comfort, and a lifetime of wear. It's the critical difference between a shoe you like for a season and one you'll treasure for decades.

What is a Goodyear Welt?

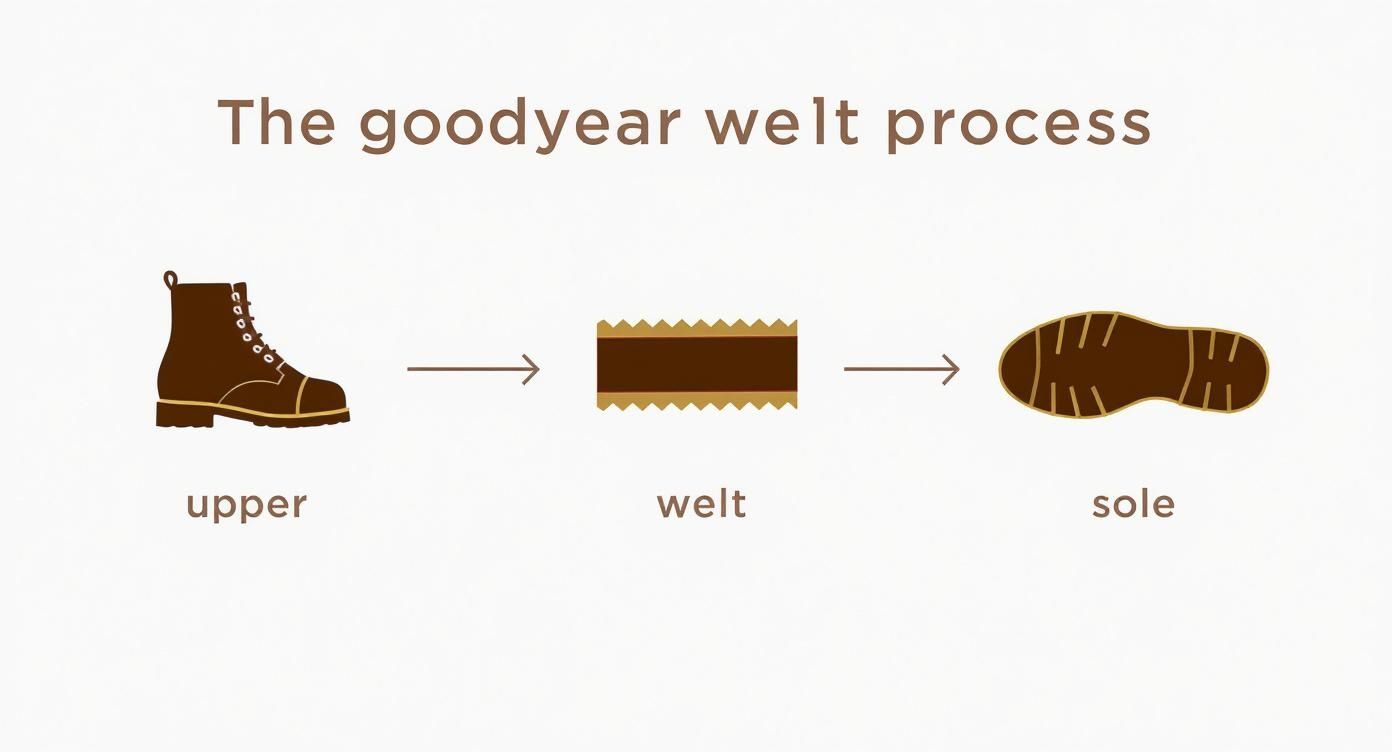

At its core, a Goodyear welt is a sophisticated method of attaching the sole of a shoe to its upper. It involves a strip of leather—the welt—that acts as a powerful intermediary. First, the welt is stitched to the shoe's upper. Then, in a separate step, the outsole is stitched directly to that same welt. This two-level stitching process creates an incredibly robust and stable structure.

This ingenious design is why Goodyear welted shoes are renowned for their strength and why they don't suffer from the sole separation that often plagues lesser-quality, glued footwear.

The Foundation of Lasting Quality

The space between the insole and the outsole, created by the welt, is filled with a layer of cork. This natural material is a marvel of engineering—it provides excellent shock absorption, insulation, and breathability. As you wear the shoes, the cork footbed gradually molds to the unique contours of your foot, creating a personalized, custom-like fit that mass-produced footwear can't replicate.

This method delivers a powerful trio of benefits:

- Exceptional Durability: The dual lockstitched seams create a bond that's built to withstand the rigors of daily life.

- Superior Water Resistance: The welt forms a protective barrier, making it significantly more difficult for water to penetrate the shoe from the ground up.

- Unmatched Repairability: This is where the Goodyear welt truly shines. Because the outsole is stitched to the welt and not the upper, a skilled cobbler can easily remove the old sole and attach a new one without compromising the shoe's core structure.

This unique construction is what separates an investment-grade shoe from a disposable one. A Goodyear welted shoe isn’t meant to last a season; it’s designed to last a lifetime with proper care and resoling.

To get a better visual, let's break down the key parts that make this construction so special.

Anatomy of a Goodyear Welted Shoe

Here’s a look at the essential parts and the specific role each one plays in creating a durable, comfortable, and repairable shoe.

| Component | Function |

|---|---|

| Upper | The main body of the shoe that covers the foot. |

| Insole | The foundation inside the shoe where your foot rests. |

| Welt | A strip of leather stitched to the upper and the insole's "rib." |

| Cork Filling | Fills the cavity between the insole and outsole for cushioning and custom molding. |

| Midsole | An optional layer between the welt and outsole for added support and durability. |

| Outsole | The bottom layer of the shoe that makes contact with the ground. |

| Lockstitching | The two independent sets of stitches that hold everything together securely. |

Each of these elements works in concert, creating a final product that is more than just the sum of its parts. It's a system designed for longevity.

A Legacy of Innovation

This time-honored technique was invented in 1869 by Charles Goodyear Jr., son of the famous inventor of vulcanized rubber. His machinery revolutionized shoemaking, mechanizing a once laborious hand-sewn process and making truly durable footwear accessible. That legacy has stood for over 150 years, and Goodyear welting remains the gold standard for quality craftsmanship.

At Alexander Noel, we build our custom footwear on this very foundation, blending this traditional artistry with modern personalization. Understanding how different Goodyear welted sole units contribute to comfort and longevity is key to designing a shoe that's truly perfect for you.

The Art and Science of the Goodyear Welt Process

Ever wonder what really separates a decent shoe from a truly exceptional one? It’s not just the gleam of the leather. It’s the hidden architecture, the patient skill baked into its very foundation by a master artisan. The Goodyear welt process isn't an assembly line; it's a carefully choreographed performance of precision, strength, and artistry.

Each step is deliberate, building on the last to create something far greater than the sum of its parts. It's a method that simply can't be rushed. By walking through these stages, you’ll see the sheer dedication poured into every pair of high-quality, handcrafted shoes.

Preparing The Foundation

It all starts with the insole—the unseen soul of the shoe. A craftsman begins by carving a perpendicular channel, or "rib," around the edge of a sturdy leather insole. This tiny ridge might look minor, but it's the anchor point for the entire shoe.

Next, the shoe's upper is meticulously stretched over a "last," which is the mold that dictates the shoe's final shape. The upper is then temporarily attached to the insole, perfectly aligned and ready for the first, most critical phase of stitching. This is where the magic really begins.

The infographic below shows how these core components fit together.

You can see how the welt acts as the essential bridge, connecting the upper to the sole without a single stitch piercing the inside of the shoe.

The Art of The Stitch

Now for the star of the show: the welt. This is a long, durable strip of leather that gets stitched through the upper and into that carefully carved insole rib. This first seam, called the inseam, is what locks the upper to the shoe’s foundation. It’s done with a powerful lockstitch, creating a bond that is both incredibly strong and surprisingly flexible.

This process creates a hollow space between the insole and the outsole. This cavity isn't just left empty. It's carefully filled with a compound, typically granulated cork, which is the perfect material for the job.

Cork is prized for its natural gifts: it's breathable, an amazing shock-absorber, and a great insulator. But its best trick? Over time, it compresses and molds to the unique shape of your foot, creating a personalized footbed that offers custom support.

This is exactly why Goodyear welted shoes get more comfortable the more you wear them. The shoe doesn’t just break in; it truly adapts to you.

Completing The Structure

With the cork filling in place, it's time for the final major piece: the outsole. This is the tough layer that hits the pavement. Instead of being attached directly to the upper, the outsole is stitched to the exposed part of the welt using a second, completely separate row of lock stitching.

This two-level stitching system is the genius of Goodyear welt construction. It creates a robust, stable, and highly water-resistant shoe. Because the stitches holding the sole on never actually enter the shoe's interior, water has a much tougher time getting in.

Finally, the shoemaker trims the excess leather from the sole’s edge, then meticulously sands, waxes, and polishes it to a smooth, elegant finish. This obsessive attention to detail is the hallmark of true craftsmanship. It's a core reason why bespoke shoes for men built this way are considered a lifelong investment—the ability to replace the sole again and again without touching the upper gives these shoes their incredible longevity.

The True Value: Durability, Comfort, and Longevity

Think of a pair of Goodyear welted shoes not as a simple purchase, but as a long-term addition to your wardrobe. Yes, the upfront cost might be higher than what you see with mass-market shoes, but the real return on that investment comes through in their incredible durability, custom-like comfort, and a lifespan that genuinely redefines value. These aren't shoes built for a single season; they're crafted to be with you for decades.

The secret to their strength is all in the stitch. Unlike a glued shoe where adhesive is the only thing holding the sole on, this method uses a tough, flexible strip of leather—the welt—to physically stitch the upper and the sole together. This creates a powerful mechanical bond that just won't give up, easily resisting the delamination and separation that inevitably kills cheaper footwear, especially after a run-in with a rain puddle or just the stress of daily walking.

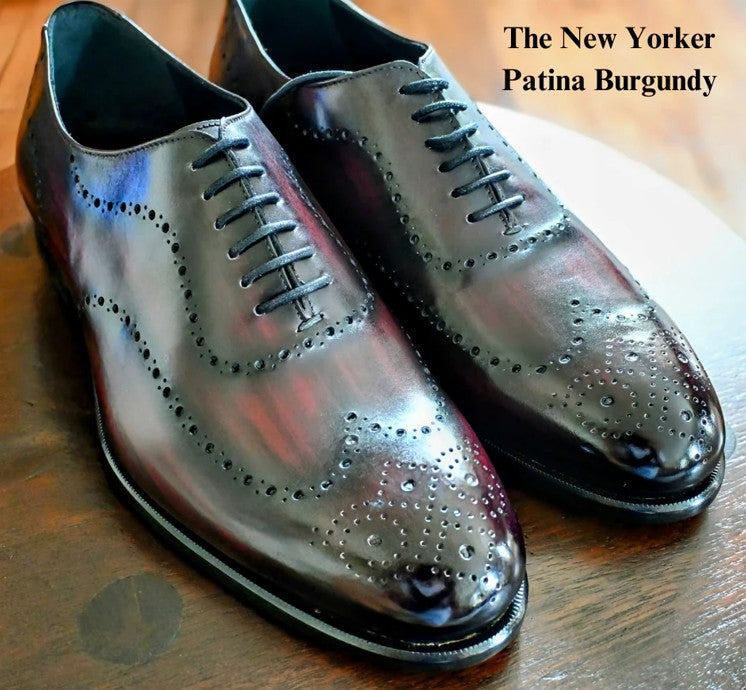

This kind of solid construction means your shoes can take whatever your day throws at them for years on end. Instead of falling apart, they develop character and a rich patina that tells a story.

Comfort That Adapts to You

Beyond just being tough, the Goodyear welt construction delivers a level of comfort that a standard cemented shoe could only dream of. The magic happens in the empty space, or cavity, created between the insole and the outsole. Our artisans pack this space with a generous layer of granulated cork. This isn't just fluffy filler; it's a key ingredient for a personalized fit.

As you wear your shoes, the warmth and pressure from your feet slowly compress the cork, causing it to mold to the unique shape and contours of your foot. Over time, this creates a custom footbed that gives you support exactly where you need it and distributes your weight perfectly.

The result is a fit that feels more and more like it was made just for you every time you put them on. This adaptive comfort is a true hallmark of Goodyear welted footwear and why they so often become the go-to pair in any collection.

At its core, the technique is brilliantly simple yet effective. A leather welt is stitched to the upper and the insole, creating a sturdy foundation. Then, the outsole is stitched to that very welt, not directly to the shoe's upper. This indirect attachment is what allows the shoe to be resoled again and again, massively extending its life—a huge advantage over cemented soles that are often a one-and-done deal.

A Smarter Long-Term Investment

Perhaps the best reason to choose a Goodyear welt is the incredible long-term value. While the skilled labor and premium materials do mean a higher initial price, the fact that they are fully repairable makes them far more economical over the years. When the sole eventually wears out from all your adventures, a good cobbler can simply snip the outsole stitches, attach a brand new sole, and give your shoes a whole new life.

This isn't a one-time fix, either. The process can be repeated multiple times without ever damaging the shoe's upper or its internal structure. Put it this way: one pair of Goodyear welted shoes can easily outlast five or more pairs of disposable, glued-sole shoes. Suddenly, it’s not just a purchase; it's a lasting investment in your personal style and a much more sustainable way to think about your wardrobe.

You're not just buying a shoe; you're getting an asset you can maintain and enjoy for years to come. The type of sole you choose also adds to this longevity. For example, exploring options like Dainite studded rubber soles for Goodyear welted shoes can make them even more durable and ready for any weather.

Comparing Goodyear Welt to Other Methods

To really get what makes a Goodyear welt so special, it helps to see how it stacks up against the other ways shoes are put together. Not all construction is created equal, and every method strikes a different balance between durability, flexibility, and of course, price. Knowing the difference is what separates a smart shopper from everyone else.

Let's put the Goodyear welt head-to-head with its two most common rivals: the Blake stitch and cemented construction. When you compare them on the things that actually matter, you start to see what real quality looks like and can pick shoes that truly fit your life. This is the kind of knowledge that lets you look past the price tag and appreciate the hidden engineering in a great pair of shoes.

The Sleek Alternative: Blake Stitch

First up, you have the Blake stitch. This method is a favorite in Italian shoemaking, and for good reason—it produces an incredibly sleek and flexible shoe. With a Blake stitch, the outsole is sewn directly to the insole and the upper in one single, continuous seam. This creates a lighter shoe with a very close-trimmed sole, giving it that elegant, graceful silhouette.

But that sleek design comes with a few trade-offs. Because that single stitch goes right through the insole, Blake-stitched shoes are far less water-resistant. A quick walk through a puddle can mean wet socks as moisture wicks its way straight into the shoe. They can be resoled, but it takes a special Blake stitching machine that not every cobbler has, making repairs a bit trickier to find.

The Mass-Market Standard: Cemented Construction

Then there’s cemented construction, the method used for the vast majority of shoes you see on the shelves, from sneakers to fast-fashion dress shoes. The process is exactly what it sounds like: the upper part of the shoe is glued to the sole using a powerful industrial adhesive. No stitches, just cement.

This makes for quick, cheap production, but the compromise is huge when it comes to durability and repair. That glue bond will inevitably break down over time, especially with exposure to moisture and the constant flexing of walking. We've all seen it happen—the dreaded sole separation. Once the sole is worn out or comes loose, the shoe is basically done for, destined for the trash. It's a method that makes sense for some footwear, but it's not built to last. You can dig deeper by exploring the art of shoe construction in our detailed guide.

Head-to-Head Comparison

To really make the differences pop, let's break down how each method performs across the most critical categories.

Shoe Construction Method Comparison

Here’s a simple chart that lays it all out, comparing Goodyear welt, Blake stitch, and cemented construction side-by-side.

| Feature | Goodyear Welt | Blake Stitch | Cemented |

|---|---|---|---|

| Durability | Excellent; built for decades of wear. | Good; flexible but less robust. | Poor; prone to sole separation. |

| Water Resistance | High; welt acts as a protective barrier. | Low; stitch allows water ingress. | Varies, but fails when glue degrades. |

| Flexibility | Stiff initially, breaks in over time. | Very high; flexible from the first wear. | High; often very flexible out of the box. |

| Repairability | Excellent; easily and repeatedly resoleable. | Moderate; requires special machinery. | None; designed to be disposable. |

| Cost | Highest initial investment. | Mid-range; less labor-intensive. | Lowest cost to produce and buy. |

This comparison really shows why the Goodyear welt has been the gold standard for high-quality footwear for so long. The invention of the Goodyear welt machine, patented way back in 1871, was a turning point for shoemaking. It allowed this superior construction to be scaled up, automating the critical welt stitching and boosting production without sacrificing the core principles of craftsmanship.

Even with its higher cost, the process is still prized today for the incredible durability and repairability it delivers—qualities that just can't be matched by faster, cheaper methods.

How Alexander Noel Delivers Modern Craftsmanship

At Alexander Noel, we don’t believe in separating timeless tradition from modern personalization. We see them as two sides of the same coin. The superior foundation of a Goodyear welt shouldn't be locked away in a few off-the-rack designs; it should be the starting point for a shoe that is uniquely, undeniably yours.

Our direct-to-consumer model is built on this very idea. We partner with world-class artisans who have dedicated their lives to mastering the intricate art of Goodyear welting. These shoemakers, from renowned footwear hubs in Spain and Portugal, bring generations of skill to every pair they create.

By fostering these direct partnerships and cutting out the middlemen, we make their incredible craftsmanship accessible. You’re not just getting a shoe with a luxury price tag; you’re connecting directly with a heritage of quality and receiving unparalleled value.

Your Vision, Built on a Solid Foundation

The artisan's commitment is only half the story. The other half is yours to write. We put the power of creation squarely in your hands with our interactive Design Lab. Here, the proven strength of a Goodyear welt becomes the blank canvas for your personal style.

This is so much more than just picking a color. You get to co-create a masterpiece from the ground up, built on a foundation that's made to last a lifetime. Our digital tools let you explore a massive library of options and watch your vision come to life in real-time.

You can hand-pick from a curated selection of premium materials and styles:

- Premium Leathers: Choose from full-grain calfskin, buttery suedes, or even exotic textures sourced from the world’s finest tanneries.

- Custom Colors: Forget standard black and brown. Explore a full spectrum of colors and hand-applied patinas that give your shoes a one-of-a-kind soul.

- Styling Details: You call the shots on everything. From the type of sole and the color of the stitching to the exact style of the broguing.

- The Perfect Fit: Because we're a made-to-order workshop, your final creation is crafted to your precise measurements for comfort that feels truly custom.

At Alexander Noel, we see the Goodyear welt not as the end of the design process, but as the beginning. It's the promise of quality and longevity upon which you can build a shoe that truly reflects who you are.

Bridging Heritage and Innovation

We believe true luxury isn't about a logo; it's about the fusion of tradition and personalization. The Goodyear welt is a legacy of quality that has proven its worth for over 150 years. Our Design Lab is the future of footwear—a future where you are the designer.

By bringing these two worlds together, we offer something that goes way beyond just shopping. It’s a creative journey. The result is more than just a better shoe; it's a piece of wearable art that tells your story, all backed by a construction method trusted for centuries. This is how we deliver modern craftsmanship, one custom pair at a time.

Caring for Your Goodyear Welted Shoes

When you invest in a pair of shoes built with a Goodyear welt, you’re not just buying footwear; you’re investing in something designed to last a lifetime. But like any quality investment, a little upkeep goes a long way.

With just a few simple habits, you can keep your shoes looking incredible for years—even decades—to come. It's not complicated, but it is the secret to getting the most out of your craftsmanship.

The Essentials of Shoe Maintenance

A solid care routine really comes down to three things: cleaning, conditioning, and storing them correctly. This isn't just about looks; it's about preserving the leather and the very structure of the shoe.

Think of it as a simple ritual:

- Cleaning: After you wear them, give your shoes a quick once-over with a horsehair brush. This knocks off the daily dust and grime before it can build up. For a more thorough job, a damp cloth and a good leather cleaner are all you need.

- Conditioning: Every couple of months, treat the leather to a high-quality conditioner or cream polish. This puts back the essential oils that keep the leather soft, hydrated, and free from cracks.

- Proper Storage: This one is a game-changer. Slide a pair of cedar shoe trees into your shoes as soon as you take them off. They'll pull out moisture, smooth out creases, and help your shoes hold their original shape perfectly.

Think of this routine as preventative medicine for your shoes. A few minutes of care after wearing them prevents long-term damage and preserves the rich character of the leather.

For more great tips on keeping your leather goods in top shape, check out a complete guide to caring for leather bags.

Knowing When to Visit a Cobbler

Here’s the real magic of a Goodyear welt: it’s built to be repaired. When the sole eventually wears down, it’s not the end of the road. It’s just time for a tune-up.

Keep an eye out for soft spots in the sole, any visible holes, or uneven wear that’s throwing off your gait. Those are your cues.

When that time comes, find a skilled cobbler who knows their way around Goodyear welted shoes. They can snip the welt stitch, remove the worn-out sole, and attach a brand new one. The best part? This doesn't affect the upper at all, bringing your trusted pair right back to life. This isn't just a repair; it's a rebirth, giving your shoes a second, third, or even fourth life.

Your Questions About Goodyear Welt, Answered

Even when you appreciate the incredible craftsmanship, it's smart to have a few questions before you invest in a pair of high-quality shoes. The world of Goodyear welt construction is filled with nuance, and getting a handle on the practical side of owning a pair is key to feeling great about your choice.

To clear things up, we've pulled together the answers to the questions we hear the most from fellow shoe lovers.

How Long Is the Break-In Period?

One of the signature traits of a Goodyear welted shoe is its initial sturdiness, which means there's a necessary break-in period. Don't worry—this is where the magic happens and the shoe truly becomes yours.

Typically, you can expect this to take anywhere from one to four weeks of consistent wear. It all comes down to the tough leather insole and the dense cork filling inside, which need a little time to compress and mold to the exact shape of your foot. It takes a bit of patience, but the payoff is a custom-like fit that other construction methods just can't match.

Are Goodyear-Welted Shoes Waterproof?

That’s a great question, and an important one. The short answer is that Goodyear welted shoes are highly water-resistant, but not completely waterproof.

The combination of the stitching and the leather welt creates a really solid barrier against moisture seeping in from the ground. This gives you way better protection from rain and puddles than you'd get from Blake-stitched or cemented shoes. That said, they aren't meant to be fully submerged. For everyday life in most weather, their water resistance is more than enough to keep you dry.

Think of it like a water-resistant watch versus a full-on diver's watch. A Goodyear welted shoe will handle a downpour without a problem, but you probably wouldn't take it for a swim.

Is the Higher Price Really Worth It?

Absolutely. It really boils down to long-term value and what we call "cost-per-wear." The upfront cost is higher, sure, but that's a direct reflection of the skilled labor and premium materials that go into making them.

The true value of a Goodyear welt shines through over the life of the shoe. Because you can have them resoled over and over, a single pair can easily last longer than three to five pairs of cheaper, throwaway shoes. Instead of buying a new pair every year, you're just maintaining one incredible pair. Over time, this makes them the smarter, more sustainable, and more economical choice. It's proof that quality is an investment that truly pays for itself.

At Alexander Noel, we believe the enduring quality of a Goodyear welt is the perfect foundation for your personal style. Begin your journey into custom, handcrafted footwear and create a pair that is uniquely yours. Start designing in our Design Lab today.

![Men's Shoe Trends 2026: 7 Game-Changing Styles [Alexander Noel Guide]](http://www.shopalexandernoel.com/cdn/shop/articles/hero_alexander_noel_final_1024x1024.png?v=1767751739)